-40%

Inconel 2.4856 Alloy 625 Schweißdrahte 0 1/32-0 1/16in Nickellegierung N06625

$ 2125.36

- Description

- Size Guide

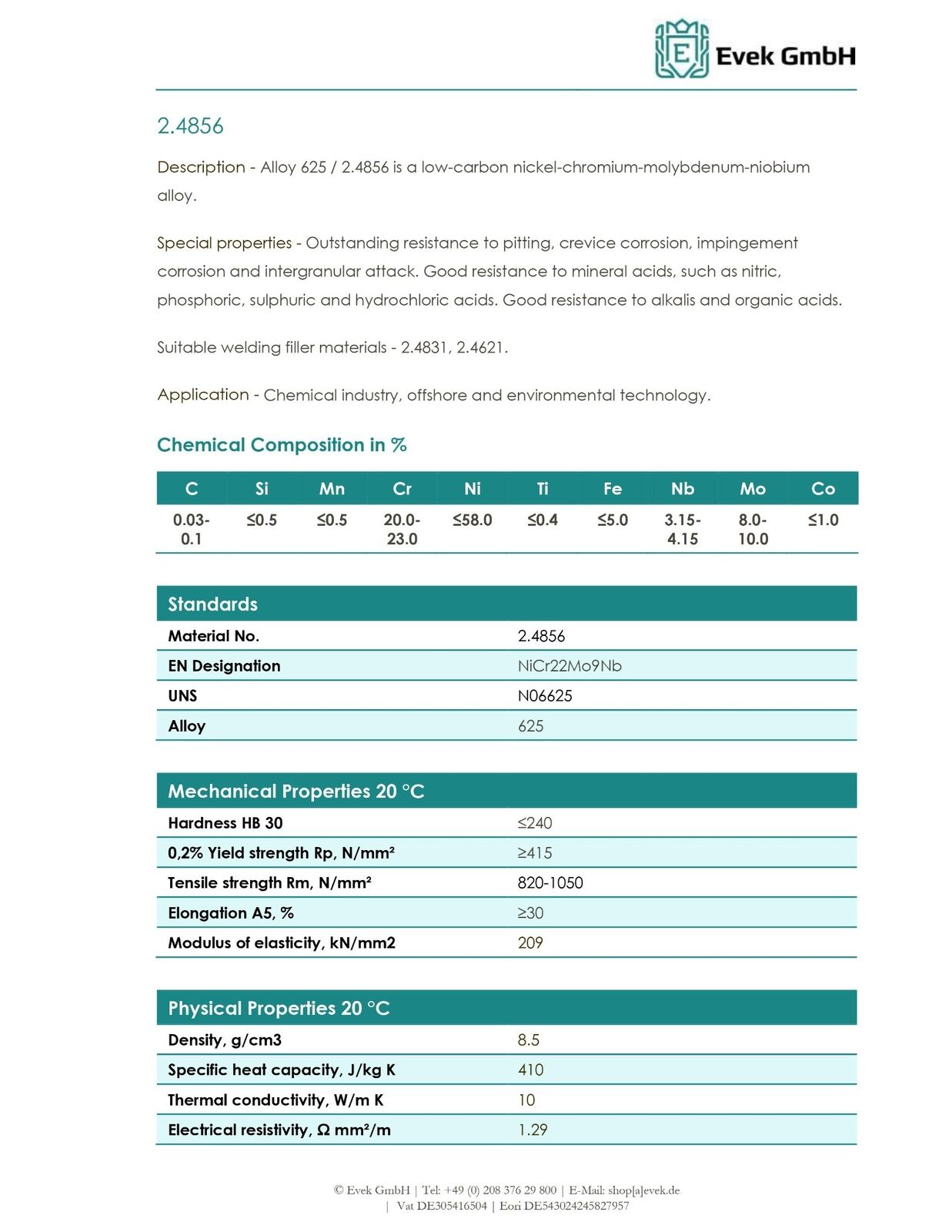

Description

Inconel® 2.4856 Alloy 625 Welding Wires 0.8-1.6mm Nickel Alloy N06625 TIG TIGInconel® 2.4856 Alloy 625 Welding Wires 0.8-1.6mm Nickel Alloy N06625 TIG TIG

Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)

Length tolerance +/-2mm

TOP quality at fair prices

High-quality products made to measure and cut to size

Competent advice & service

Technical specifications:

Brand:

Evek

Manufacturer number:

Not applicable

Type:

wire

Material:

nickel

Areas of application:

chemical industry (for the production of mineral acids); Oil and gas extraction installations; Installations for processing radioactive waste; offshore and marine engineering; Shipbuilding; seawater pipes; chimney linings;

Characteristics:

excellent resistance in many corrosive environments; good mechanical properties in a wide temperature range; extreme resistance to a variety of types of corrosion (pitting, crevice, erosion and intergranular corrosion); good resistance to organic and mineral acids; good resistance to alkalis; very good resistance in media containing chloride;

Norm classifications:

Material number:

2.4856

Alloy:

625

US:

N06625

Further information:

Density:

8.5 g/cc

melting point:

1290°C

thermal conductivity:

9.8 W/m K

electr. Resistance:

1.28Ω•mm²/m

Description:

Production time - 2-3 weeks.

Preparation for shipment - 2-3 working days.

Look at the FAQ please.

Inconel® 625 is a heat-resistant, low-carbon alloy composed of nickel, chromium, molybdenum and niobium. It shows excellent resistance in many corrosive environments and has good mechanical properties over a wide temperature range. Alloy 625 is characterized by its extreme resistance to a large number of types of corrosion (pitting, crevice, erosion and intergranular corrosion). 2.4856 is not susceptible to organic and mineral acids. The grade is also resistant to alkalis. Furthermore, the material shows very good resistance in media containing chloride.

Due to its excellent resistance to acids and alkalis, Inconel® 625 is used in the chemical industry to produce mineral acids. The material is also used in oil and gas production facilities and radioactive waste processing facilities. Other areas of application for Alloy 625 are:

offshore and marine engineering;

Shipbuilding;

seawater pipes;

chimney liners.

2.4856 is characterized by:

excellent resistance in many corrosive environments;

good mechanical properties in a wide temperature range;

extreme resistance to a variety of types of corrosion (pitting, crevice, erosion and intergranular corrosion);

good resistance to organic and mineral acids;

good resistance to alkalis;

very good resistance in media containing chloride.

documentation

Data sheet (German)

d — outer diameter

Listing and template services provided by inkFrog

excellent resistance in many corrosive environments; good mechanical properties in a wide temperature range; extreme resistance to a variety of types of corrosion (pitting, crevice, erosion and intergranular corrosion); good resistance to organic and mineral acids; good resistance to alkalis; very good resistance in media containing chloride; Inconel® 625 is a heat-resistant, low-carbon alloy composed of nickel, chromium, molybdenum and niobium. It shows excellent resistance in many corrosive environments and has good mechanical properties over a wide temperature range. Alloy 625 is characterized by its extreme resistance to a large number of types of corrosion (pitting, crevice, erosion and intergranular corrosion). 2.4856 is not susceptible to organic and mineral acids. The grade is also