-40%

Inconel 601 Alloy Stange 0 1/4-1 31/32in 2.4851 round Rod N06601

$ 1930.42

- Description

- Size Guide

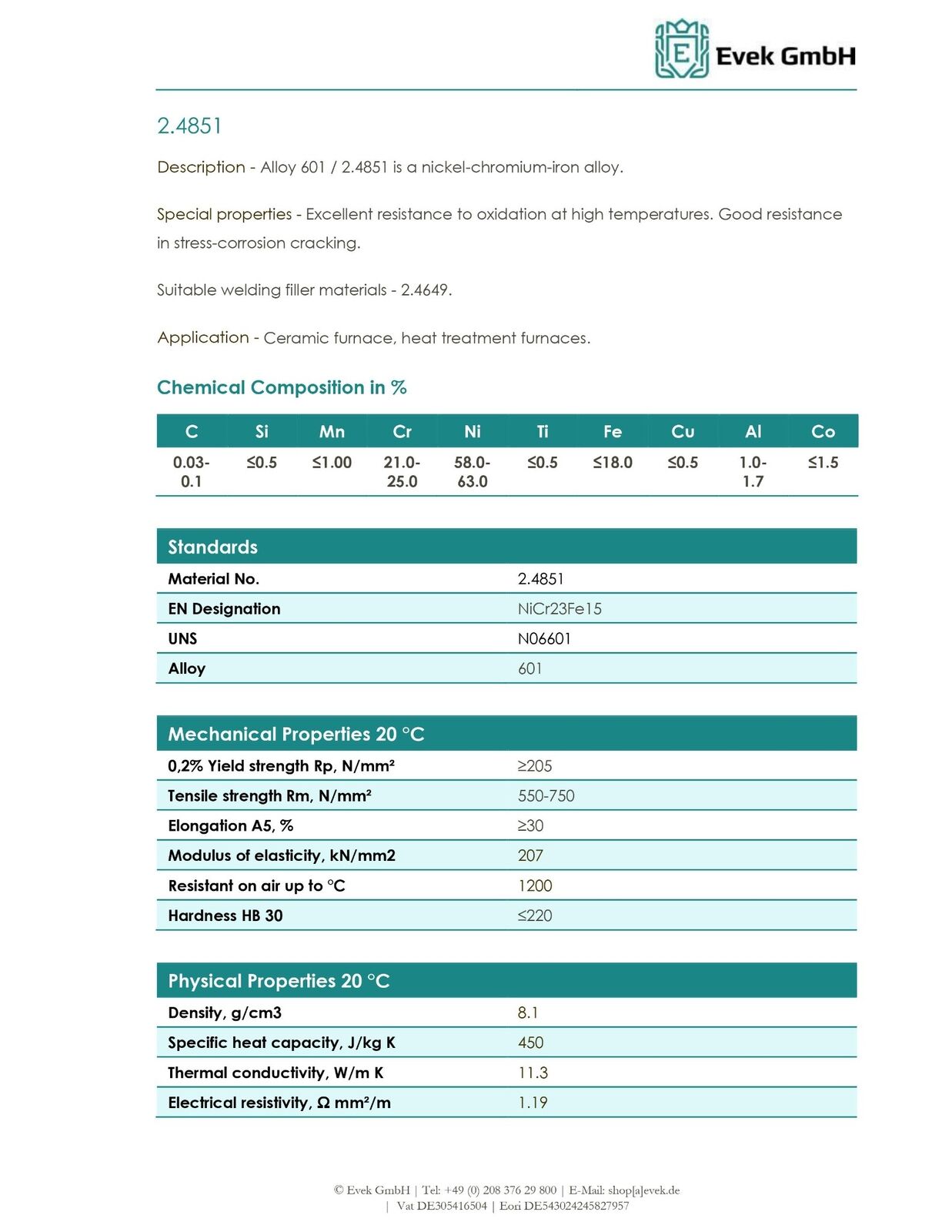

Description

Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)Length tolerance +/-2mm

TOP quality at fair prices

High-quality products made to measure and cut to size

Competent advice & service

Technical specifications:

Brand:

Evek

Manufacturer number:

Not applicable

Type:

rod, rod

Material:

nickel

Areas of application:

Furnace construction (various components); gas turbine parts; heat treatment plants; chemical industry; environmental protection systems; automotive industry (components for diesel engines); ash conveyor (various components);

Characteristics:

excellent resistance to oxidation at high temperatures; usable in sulphurous environments; very good scaling resistance and high heat resistance; operating temperature range up to 1150 °C; good resistance under carburizing conditions; good resistance to aggressive gases

Norm classifications:

Material number:

2.4851

US:

N06601

Further information:

Density:

8.1 g/cc

melting point:

1320°C

thermal conductivity:

11.3 W/m K

electr. Resistance:

1.03Ω·mm²/m

Description:

Production time - 2-3 weeks.

Preparation for shipment - 2-3 working days.

Look at the FAQ please.

Inconel® 601 is an alloy of nickel, chromium and iron. It also contains a small amount of aluminum and titanium. The material offers excellent resistance to oxidation at high temperatures. 2.4851 can also be used in sulphurous environments. The material has very good scaling resistance and high heat resistance and can therefore be used at temperatures of up to 1150 °C. The grade has good resistance under carburizing conditions and against aggressive gases.

2.4851 is mainly used in furnace construction (various components) and for gas turbine parts. Other areas of application for Inconel® 601 are:

heat treatment plants;

chemical industry;

environmental protection systems;

automotive industry (components for diesel engines);

Ash conveyor (various components).

The following features characterize 2.4851:

excellent resistance to oxidation at high temperatures;

very good scaling resistance and high heat resistance;

Operating temperature range up to 1150 °C;

good resistance under carburizing conditions;

good resistance to aggressive gases.

documentation

Data sheet (German)

d — outer diameter

Listing and template services provided by inkFrog

Furnace construction (various components); gas turbine parts; heat treatment plants; chemical industry; environmental protection systems; automotive industry (components for diesel engines); ash conveyor (various components); excellent resistance to oxidation at high temperatures; usable in sulphurous environments; very good scaling resistance and high heat resistance; operating temperature range up to 1150 °C; good resistance under carburizing conditions; good resistance to aggressive gases Inconel® 601 is an alloy of nickel, chromium and iron. It also contains a small amount of aluminum and titanium. The material offers excellent resistance to oxidation at high temperatures. 2.4851 can also be used in sulphurous environments. The material has very good scaling resistance and high heat re