-40%

Inconel Alloy 601 Pipe 2.4851 round Tube 2.75x0.5-141.3 Х 6.2 5/32in Soldered

$ 1865.95

- Description

- Size Guide

Description

Inconel® Alloy 601 tube 2.4851 round tube 2.75x0.5-141.3х6.55mm weldedInconel® Alloy 601 tube 2.4851 round tube 2.75x0.5-141.3х6.55mm welded

Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)

TOP quality at fair prices

High-quality products made to measure and cut to size

Competent advice & service

Length tolerance +/-2mm

Technical specifications:

Brand:

Evek

Manufacturer number:

Not applicable

Type:

Pipe

Material:

nickel

Operation area:

tanks and pipes for storing alkaline solutions; thermocouple protection tubes;

automotive industry; industrial furnace construction; Reaction vessels and heat exchanger tubes in the production of vinyl chloride

Norm classifications:

Material number:

2.4851

EN:

NiCr15Fe

US:

N06601

Further information:

Density:

8.1 g/cc

thermal conductivity:

11.3 W/m K

electr. Resistance:

1.03Ωmm²/m

Surface:

smooth (may contain handling or storage marks)

Description:

Production time - 2-3 weeks.

Preparation for shipment - 2-3 working days.

Look at the FAQ please.

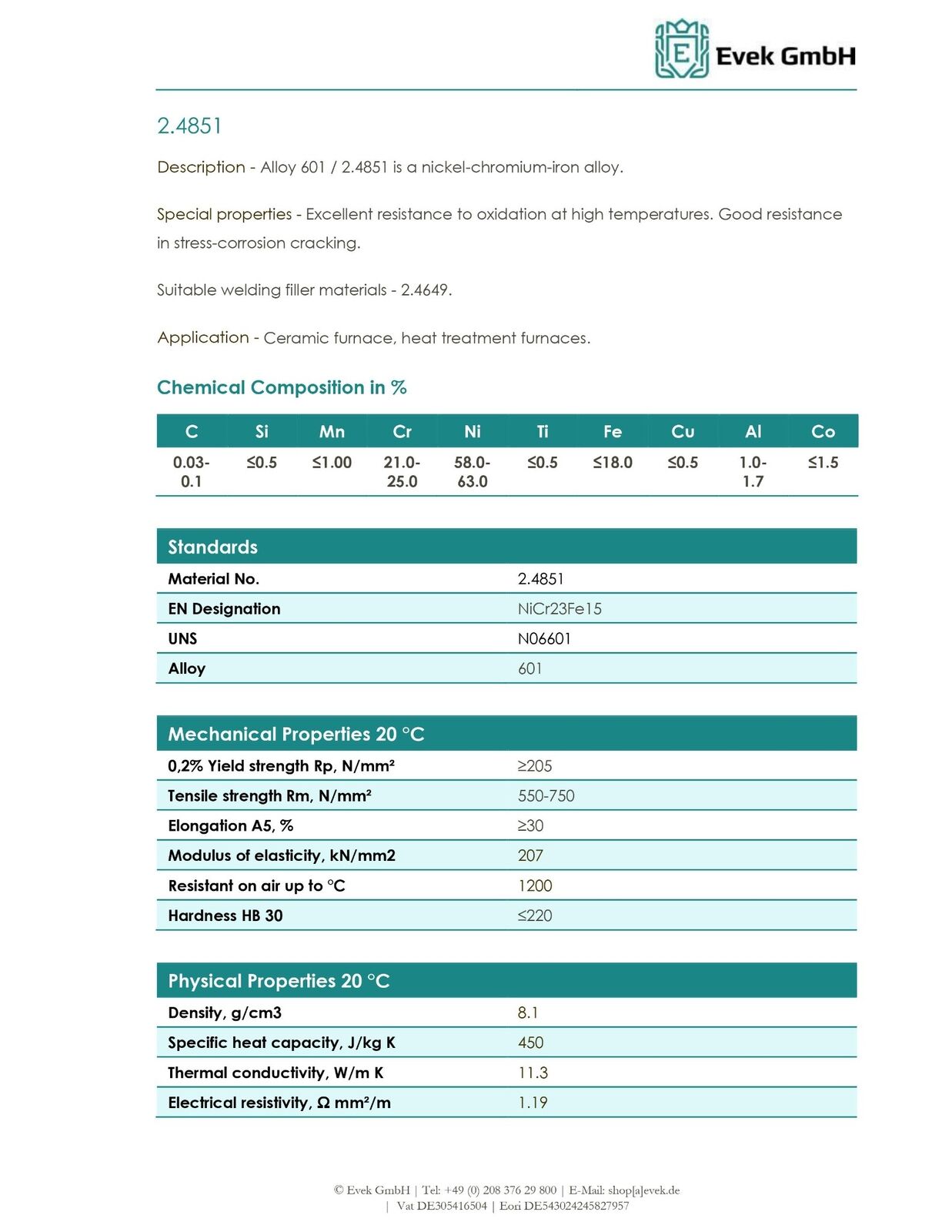

2.4851 tubing is produced from a nickel-chromium-iron alloy. This has good resistance to corrosion and stress corrosion cracking. The tube has excellent resistance to oxidation up to approx. 1150ºC. In the annealed condition, it can be easily welded using Allen common methods. The material is easy to solder and hard solder and has very good ductility.

Inconel® 601 tubing has very good mechanical properties at low, room and elevated temperatures. The alloy is insensitive to dry chlorine and hydrogen chloride as well as to carburization and nitrous oxide.

Typical areas of application for 2.4851 tube are:

industrial furnace construction;

tanks and pipes for storing alkaline solutions;

automotive industry;

reaction vessels and heat exchanger tubes in the production of vinyl chloride;

Thermocouple Protection Tubes.

Alloy 601 tube has the following characteristics:

good resistance to corrosion and stress corrosion cracking;

Excellent resistance to oxidation up to approx. 1150°C;

good weldability with Allen common processes;

good ductility;

Insensitivity to dry chlorine and hydrogen chloride as well as to carburization and nitrification.

documentation

Data sheet (German)

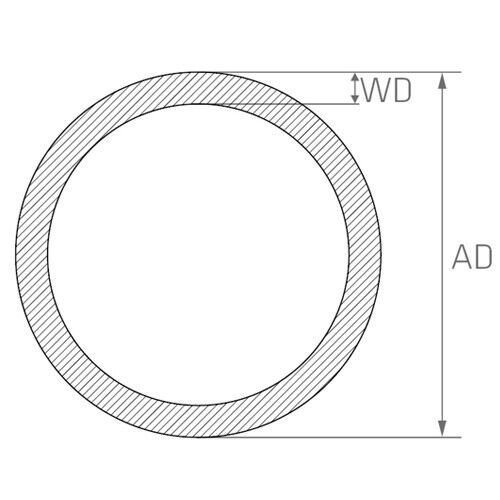

d - outside diameter

s - wall thickness

Listing and template services provided by inkFrog

Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :) automotive industry; industrial furnace construction; Reaction vessels and heat exchanger tubes in the production of vinyl chloride 2.4851 tubing is produced from a nickel-chromium-iron alloy. This has good resistance to corrosion and stress corrosion cracking. The tube has excellent resistance to oxidation up to approx. 1150ºC. In the annealed condition, it can be easily welded using Allen common methods. The material is easy to solder and hard solder and has very good ductility. Inconel® 601 tubing has very good mechanical properties at low, room and elevated temperatures. The alloy is insensitive to dry chlorine and hydrogen chloride as well as