-40%

Nicrofer S 7020 2.4806 Alloy 82 Welding Wire 0 1/32-0 1/16in N06082 Inconel 82

$ 3505.38

- Description

- Size Guide

Description

Nicrofer® S 7020 2.4806 alloy 82 welding wire 0.8-1.6mm N06082 Inconel® 82Nicrofer® S 7020 2.4806 alloy 82 welding wire 0.8-1.6mm N06082 Inconel® 82

Do you need a different steel quality or dimension? Please write to us. Our sales team makes an offer from stock program or delivery program :)

Length tolerance +/-2mm

TOP quality at fair prices

High-quality products made to measure and cut to size

Competent advice & service

Technical specifications:

Brand:

Evek

Manufacturer number:

Not applicable

Type:

welding wire

Material:

nickel

Area of application:

Joint welding on NiCrFe alloys, heat-resistant austenitic steels, cold-resistant steels, black and white joints with operating temperatures >300°C and dissimilar materials, eg copper with ferrous materials;

Characteristics:

suitable for mixed joints between ferritic carbon-manganese and austenitic chromium-nickel steels; high resistance to stress cracking and intergranular corrosion; good toughness properties down to -196 °C; Max. operating temperatures up to +900 °C;

Norm classifications:

Material number:

2.4806

Stretch limit:

400 N/mm²

Tensile strenght:

650 N/mm²

Elongation at break:

35%

AWS A-5.14:

ER CrNi-3

din ISO 18274:

NiCr20Mn3Nb (SNi 6082)

Description:

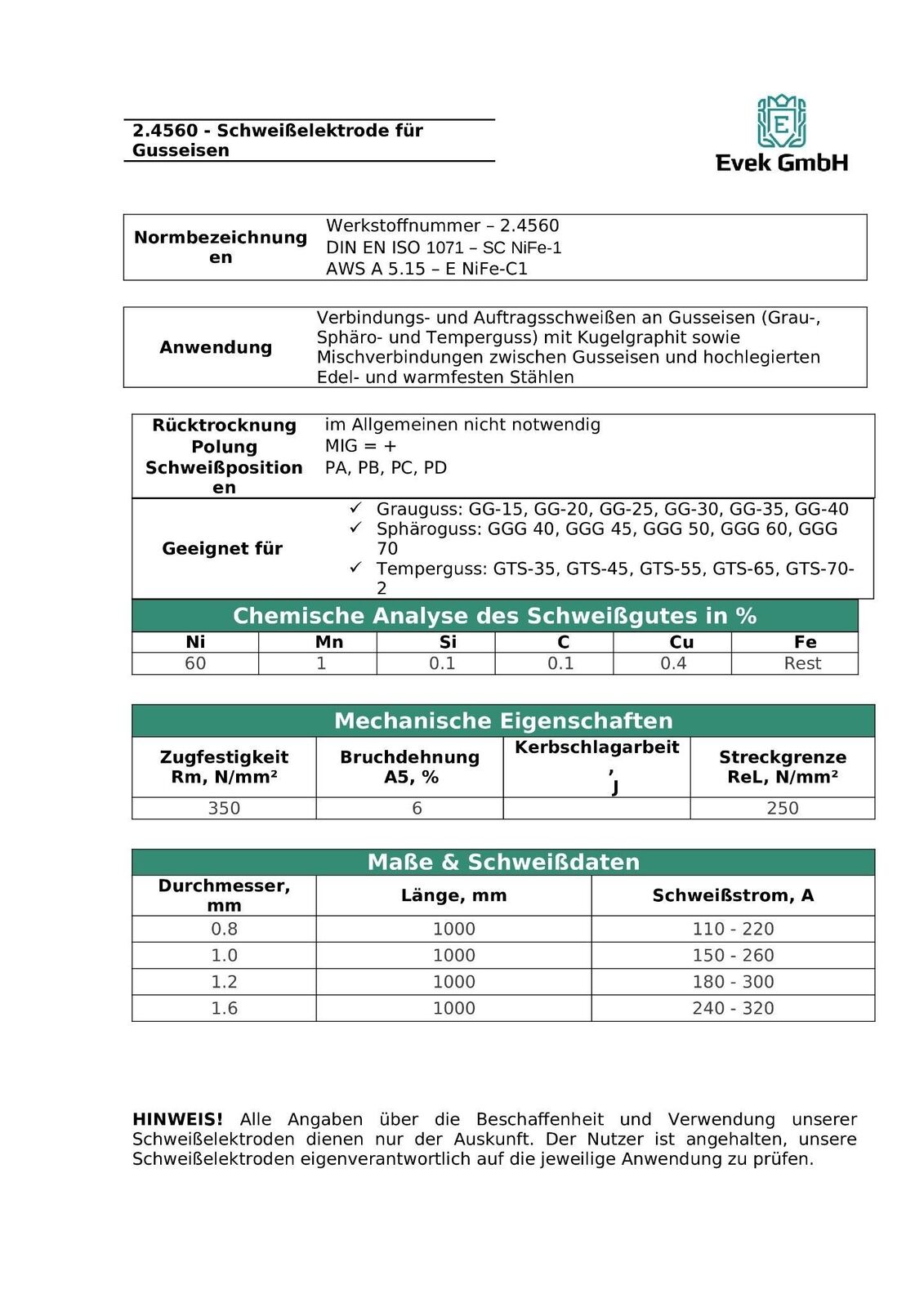

2.4560 is a filler metal made from nickel-iron alloy. The nickel content is 60%. The 2.4560 filler metal has good toughness and crack resistance and is characterized by excellent homogeneity. The weld metal is used for repair welding of castings, gears, reducers, pump parts and valve bodies.

The 2.4560 filler metal is suitable for joint and build-up welding on cast iron (grey, nodular and malleable iron) with nodular graphite as well as mixed joints between cast iron and high-alloy stainless and heat-resistant steels. Important base materials are:

Gray iron: GG-15, GG-20, GG-25, GG-30, GG-35, GG-40

Ductile iron: GGG 40, GGG 45, GGG 50, GGG 60, GGG 70

Malleable iron: GTS-35, GTS-45, GTS-55, GTS-65, GTS-70-2

The 2.4560 welding wire is characterized by the following features:

nickel-iron alloy;

good toughness and crack resistance;

excellent homogeneity.

documentation

Data sheet (German)

d — outer diameter

Listing and template services provided by inkFrog

suitable for mixed joints between ferritic carbon-manganese and austenitic chromium-nickel steels; high resistance to stress cracking and intergranular corrosion; good toughness properties down to -196 °C; Max. operating temperatures up to +900 °C; 2.4560 is a filler metal made from nickel-iron alloy. The nickel content is 60%. The 2.4560 filler metal has good toughness and crack resistance and is characterized by excellent homogeneity. The weld metal is used for repair welding of castings, gears, reducers, pump parts and valve bodies. The 2.4560 filler metal is suitable for joint and build-up welding on cast iron (grey, nodular and malleable iron) with nodular graphite as well as mixed joints between cast iron and high-alloy stainless and heat-resistant steels. Important base materials ar