-40%

Waspaloy 2.4654 Alloy 685 Schweißdrahte 0 1/16in Nickellegierung N07001 Wig Tig

$ 3436.01

- Description

- Size Guide

Description

Waspaloy® 2.4654 Alloy 685 Welding Wires 1.2mm Nickel Alloy N07001 TIG TIGWaspaloy® 2.4654 Alloy 685 Welding Wires 1.2mm Nickel Alloy N07001 TIG TIG

Do you need a different steel quality or dimensions? Please write to us. Our sales team makes an offer from stock program or delivery program :)

Length tolerance +/-2mm

TOP quality at fair prices

High-quality products made to measure and cut to size

Competent advice & service

Technical specifications:

Brand:

Evek

Manufacturer number:

Not applicable

Type:

welding wire

Material:

nickel

Areas of application:

gas turbine drive parts; Feather; fasteners; aviation industry;

Characteristics:

good corrosion resistance: very high strength at high temperatures; excellent heat resistance; high resistance to oxidation;

Norm classifications:

Material number:

2.4654

Alloy:

685

US

N07001

Further information:

melting point:

1330°C

shear modulus:

81kN/mm²

Modulus of elasticity:

211kN/mm²

Density:

8.16 g/cc

Description:

The material 2.4654 indicates temperature resistance up to 650 °C for critical applications and 870 °C for simpler applications and good corrosion resistance at high temperatures. The high-temperature strength of the alloy is achieved through solid solution strengthening elements, molybdenum, cobalt and chromium, and aging elements, aluminum and titanium. The strength and stability ranges of 2.4654 are higher than Alloy 718.

The oxidation resistance of alloy 2.4654 is good under conditions of frequent thermal cycling and continuous exposure to temperatures up to 1038 °C. It has performed well in the atmospheres and salt spray environments found in gas turbine engine operation. This material offers the best corrosion resistance.

Other areas of application for 2.4654 are:

Feather;

fasteners;

aviation industry.

Material 2.4654 is characterized by the following features:

good corrosion resistance;

very high strength at high temperatures;

excellent heat resistance;

high resistance to oxidation;

documentation

Data sheet (German)

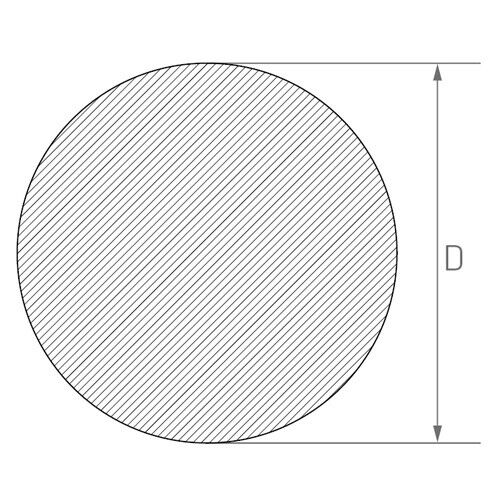

d — outside diameter

Listing and template services provided by inkFrog

Do you need a different steel quality or dimensions? Please write to us. Our sales team makes an offer from stock program or delivery program :) The material 2.4654 indicates temperature resistance up to 650 °C for critical applications and 870 °C for simpler applications and good corrosion resistance at high temperatures. The high-temperature strength of the alloy is achieved through solid solution strengthening elements, molybdenum, cobalt and chromium, and aging elements, aluminum and titanium. The strength and stability ranges of 2.4654 are higher than Alloy 718. The oxidation resistance of alloy 2.4654 is good under conditions of frequent thermal cycling and continuous exposure to temperatures up to 1038 °C. It has performed well in the atmospheres and salt spray environments found in