-40%

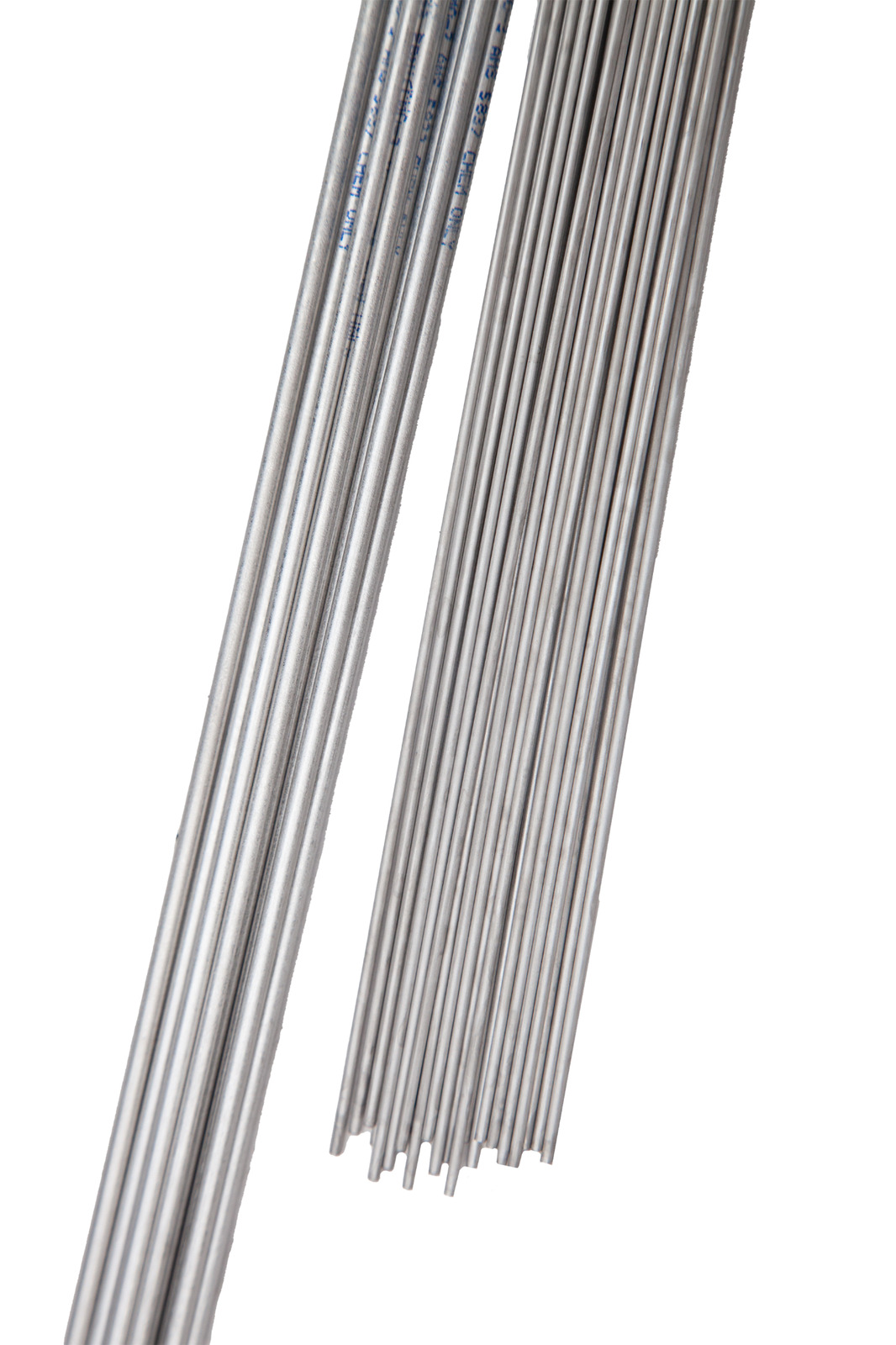

Welding Electrodes Inconel 625 Ø 0 1/32-0 3/16in Wire Nickel 2.4831 Rods

$ 12.19

- Description

- Size Guide

Description

Welding electrodes Inconel 625 Ø 0.8-5mm welding wire nickel 2.4831 welding rodsWelding electrodes Inconel 625 Ø 0.8-5mm welding wire nickel 2.4831 welding rods

100% no China imports (pay attention to high price differences)

Our products are mostly made in Germany

High quality at best prices.

TOP rating & service

Technical specifications:

Brand:

Evek

Manufacturing Country And Region:

Germany

Manufacturer number:

Not applicable

Type:

welding electrodes; welding rod

Norm classifications:

Material number:

2.4831

AWS A-5.14 :

ERNiCrMo-3

ISO 18274:

G Ni Cr 22 Mo 9 Nb

Description:

Nickel, chromium, molybdenum alloys are widely used in the aerospace, nuclear and chemical industries, but also find application in waste furnaces to withstand high temperatures in combination with burning gases. The brand's most common alloy is Inconel 625. This nickel, chromium and molybdenum alloy is available in Allen possible sizes and shapes from TIG rod to strip for submerged arc welding or electroslag processes.

Further information:

0.2% proof stress Rp0.2 — 490 N/mm²

Tensile strength Rm — 740 N/mm²

Elongation A5 — 37%

Impact strength KV — (20 °C) 130 J / (-40 °C) 150 J

documentation

Data sheet (German)

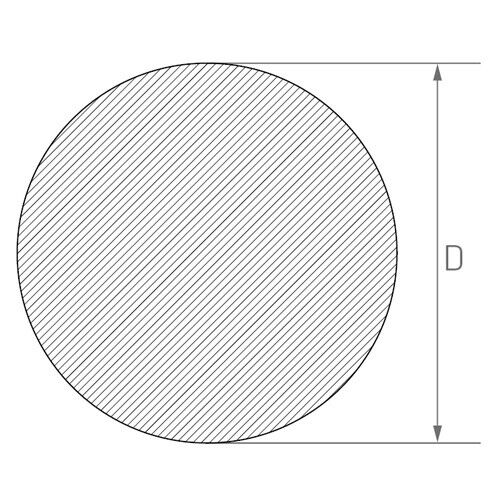

d - outside diameter

Listing and template services provided by inkFrog

Welding electrodes Inconel 625 Ø 0.8-5mm welding wire nickel 2.4831 welding rods Welding electrodes Inconel 625 Ø 0.8-5mm welding wire nickel 2.4831 welding rods 100% no China imports (pay attention to high price differences) Our products are mostly made in Germany Nickel, chromium, molybdenum alloys are widely used in the aerospace, nuclear and chemical industries, but also find application in waste furnaces to withstand high temperatures in combination with burning gases. The brand's most common alloy is Inconel 625. This nickel, chromium and molybdenum alloy is available in Allen possible sizes and shapes from TIG rod to strip for submerged arc welding or electroslag processes. 0.2% proof stress Rp0.2 — 490 N/mm² Impact strength KV — (20 °C) 130 J / (-40 °C) 150 J Listing and template