-40%

Welding Wire 1.4591 Alloy 33 Ø 0 3/32-0 3/32in Wig Welding Rods Nicrofer 3033

$ 1272.86

- Description

- Size Guide

Description

Welding wire 1.4591 Alloy 33 Ø 2-2.4mm TIG welding rods Nicrofer® 3033Welding wire 1.4591 Alloy 33 Ø 2-2.4mm TIG welding rods Nicrofer® 3033

Do you need a different steel quality or dimensions? Please write to us. Our sales team makes an offer from stock program or delivery program :)

Length tolerance +/-2mm

TOP quality at fair prices

High-quality products made to measure and cut to size

Competent advice & service

Technical specifications:

Brand:

Evek

Manufacturer number:

Not applicable

Type:

welding electrodes

Material:

nickel

Area of application:

Connection and build-up welding on similar and similar highly corrosion-resistant rolled and cast materials;

Characteristics:

excellent welding properties; excellent resistance to pitting, crevice and stress corrosion cracking in media containing chloride; good corrosion resistance in oxidizing acids, hot caustic soda and sea water;

Norm classifications:

Material number:

1.4591

Alloy:

33

din EN18274

SZ 33 32 1 Cu NL

AWS 5.9:

ER33-31

Further information:

Stretch limit:

500 N/mm²

Elongation at break:

35%

Tensile strenght:

750 N/mm²

Impact work:

90 years

Description:

1.4591 is an austenitic filler metal made from nickel-chromium-iron-molybdenum alloy. The 1.4591 welding wire is characterized by its excellent resistance to various types of corrosion such as pitting, crevice and stress corrosion in media containing chloride. The 1.4591 filler metal also shows good corrosion resistance in oxidizing acids, hot caustic soda and in sea water. The weld metal has excellent welding properties.

The 1.4591 filler metal is suitable for joint and build-up welding on similar and similar highly corrosion-resistant rolled and cast materials. However, the main base material is Alloy 33 or Nicrofer 3033.

The 1.4591 welding wire has the following features:

excellent welding properties;

Excellent resistance to pitting, crevice and stress corrosion cracking in media containing chloride

good corrosion resistance in oxidizing acids, hot caustic soda and sea water.

documentation

Data sheet (German)

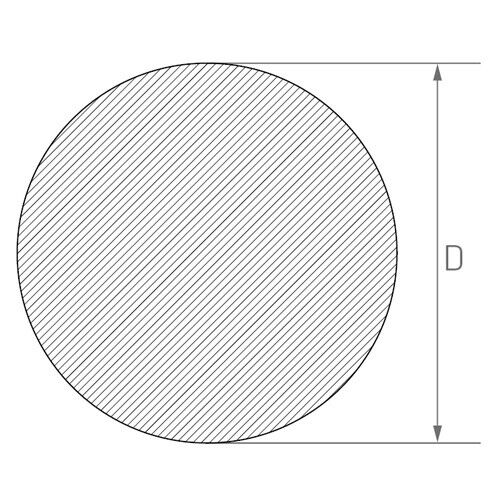

d — outside diameter

Listing and template services provided by inkFrog

excellent welding properties; excellent resistance to pitting, crevice and stress corrosion cracking in media containing chloride; good corrosion resistance in oxidizing acids, hot caustic soda and sea water; 1.4591 is an austenitic filler metal made from nickel-chromium-iron-molybdenum alloy. The 1.4591 welding wire is characterized by its excellent resistance to various types of corrosion such as pitting, crevice and stress corrosion in media containing chloride. The 1.4591 filler metal also shows good corrosion resistance in oxidizing acids, hot caustic soda and in sea water. The weld metal has excellent welding properties. The 1.4591 filler metal is suitable for joint and build-up welding on similar and similar highly corrosion-resistant rolled and cast materials. However, the main bas