-40%

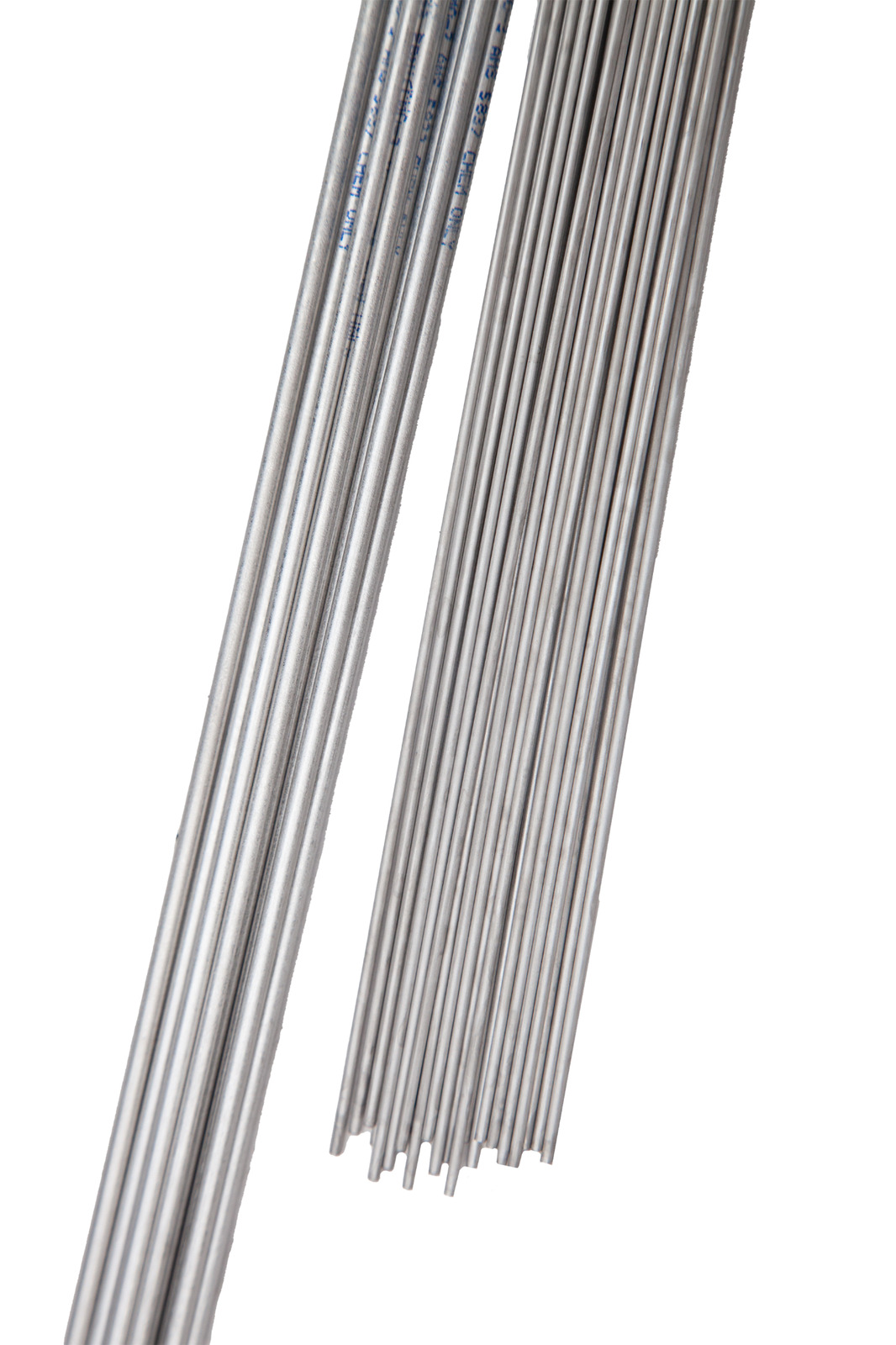

Welding Wire 2.4607 NiCrMo13 Nickel Ø 0 1/16-0 1/8in Wig Tig Rods Electrodes

$ 1735.72

- Description

- Size Guide

Description

Welding wire 2.4607 NiCrMo13 nickel Ø 1.6-3.2mm TIG TIG welding rods electrodesWelding wire 2.4607 NiCrMo13 nickel Ø 1.6-3.2mm TIG TIG welding rods electrodes

Do you need a different steel quality or dimensions? Please write to us. Our sales team makes an offer from stock program or delivery program :)

Length tolerance +/-2mm

TOP quality at fair prices

High-quality products made to measure and cut to size

Competent advice & service

Technical specifications:

Brand:

Evek

Manufacturer number:

Not applicable

Type:

welding electrodes

Material:

nickel

Area of application:

Joint and build-up welding on nickel-based alloys, duplex and super-duplex steels. Mixed compounds between steels and nickel alloys;

Characteristics:

low carbon; high resistance to hot, acidic and chloride-containing media; excellent resistance under oxidizing and reducing conditions (hydrochloric, sulfuric, phosphoric and nitric acids); scaling resistant up to 1100°C;

Norm classifications:

Material number:

2.4607

Alloy:

59

din EN18274

S Ni 6059 (NiCr23Mo16)

AWS 5.14:

ER NiCrMo-13

Further information:

Stretch limit:

450 N/mm²

Elongation at break:

35%

Tensile strenght:

720 N/mm²

Impact work:

90 years

Description:

2.4607 is a low carbon (0.01%) nickel-chromium-molybdenum alloy filler metal. The 2.4607 welding wire has high resistance to a variety of corrosive media such as hot, acidic and chloride-containing media. The 2.4607 filler metal also shows excellent resistance under oxidizing and reducing conditions (hydrochloric, sulfuric, phosphoric and nitric acid). It is scale-resistant up to 1100°C.

The 2.4607 filler metal is suitable for joint and build-up welding on nickel-based alloys, duplex and super-duplex steels, and for dissimilar joints between steels and nickel alloys. Important base materials are:

1.4562

2.4602, 2.4605, 2.4610

2.4819, 2.4856

Alloy 31, Alloy 59

The 2.4607 welding wire is characterized by the following properties:

low carbon;

high resistance to hot, acidic and chloride-containing media;

excellent resistance under oxidizing and reducing conditions (hydrochloric, sulfuric, phosphoric and nitric acids);

scaling resistant up to 1100°C.

documentation

Data sheet (German)

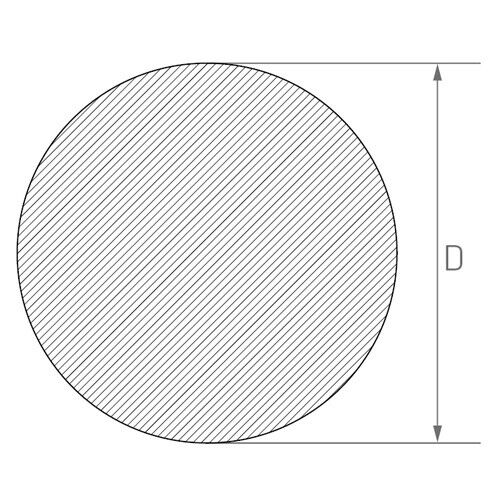

d — outside diameter

Listing and template services provided by inkFrog

low carbon; high resistance to hot, acidic and chloride-containing media; excellent resistance under oxidizing and reducing conditions (hydrochloric, sulfuric, phosphoric and nitric acids); scaling resistant up to 1100°C; 2.4607 is a low carbon (0.01%) nickel-chromium-molybdenum alloy filler metal. The 2.4607 welding wire has high resistance to a variety of corrosive media such as hot, acidic and chloride-containing media. The 2.4607 filler metal also shows excellent resistance under oxidizing and reducing conditions (hydrochloric, sulfuric, phosphoric and nitric acid). It is scale-resistant up to 1100°C. The 2.4607 filler metal is suitable for joint and build-up welding on nickel-based alloys, duplex and super-duplex steels, and for dissimilar joints between steels and nickel alloys. Imp