-40%

Welding Wire Monel 67 Nickel 2.0837 Ø 0 1/16-0 1/8in Wig Tig Rods Cuni Elect

$ 1041.42

- Description

- Size Guide

Description

Welding wire Monel® 67 Nickel 2.0837 Ø 1.6-3.2mm TIG TIG welding rods CuNi elecWelding wire Monel® 67 Nickel 2.0837 Ø 1.6-3.2mm TIG TIG welding rods CuNi elec

Do you need a different steel quality or dimensions? Please write to us. Our sales team makes an offer from stock program or delivery program :)

Length tolerance +/-2mm

TOP quality at fair prices

High-quality products made to measure and cut to size

Competent advice & service

Technical specifications:

Brand:

Evek

Manufacturer number:

Not applicable

Type:

welding electrodes; welding rod

Material:

nickel

Areas of application:

Joint welding on copper-nickel alloys, copper alloys and build-up welding of similar alloys up to 30% nickel;

Characteristics:

copper-based; very good resistance to corrosion and seawater; for welded joints and deposits of similar Cu-Ni alloys up to 30% nickel; for use in marine technology and in the chemical industry;

Norm classifications:

Material number:

2.0837

Alloy:

67

Further information:

Stretch limit:

200 N/mm²

Elongation at break:

36%

Tensile strenght:

420 N/mm²

Impact work:

240 y

Description:

2.0837 is a copper-nickel alloy filler metal with a nickel content of up to 30%. It is suitable for welded joints and deposits of similar Cu-Ni alloys up to 30% nickel. The 2.0837 welding wire has very good corrosion resistance, especially in seawater environments. Because of its excellent resistance to seawater, 2.0837 filler metal is in great demand in shipbuilding, marine engineering and the chemical industry.

The 2.0837 filler metal is suitable for joint welding on copper-nickel alloys, copper alloys and build-up welding of similar alloys up to 30% nickel. The most important base materials are:

2.0830;

2.0842;

2.0872, 2.0878;

2.0882;

Monel 450, Nickel 200.

The 2.0837 welding wire has the following features:

copper-based;

very good resistance to corrosion and seawater;

for welded joints and deposits of similar Cu-Ni alloys up to 30% nickel;

for use in marine technology and in the chemical industry.

documentation

Data sheet (German)

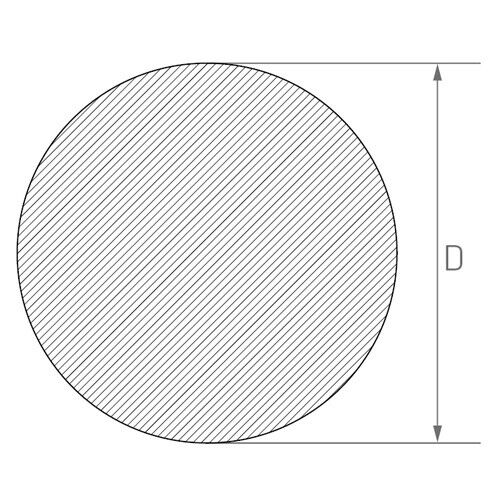

d — outside diameter

Listing and template services provided by inkFrog

Do you need a different steel quality or dimensions? Please write to us. Our sales team makes an offer from stock program or delivery program :) copper-based; very good resistance to corrosion and seawater; for welded joints and deposits of similar Cu-Ni alloys up to 30% nickel; for use in marine technology and in the chemical industry; 2.0837 is a copper-nickel alloy filler metal with a nickel content of up to 30%. It is suitable for welded joints and deposits of similar Cu-Ni alloys up to 30% nickel. The 2.0837 welding wire has very good corrosion resistance, especially in seawater environments. Because of its excellent resistance to seawater, 2.0837 filler metal is in great demand in shipbuilding, marine engineering and the chemical industry. The 2.0837 filler metal is suitable for join